- How Often Should FEC Equipment Be Inspected and Maintained? The Multi-Tiered Approach

- TL;DR: MARWEY’s Essential Maintenance Protocol

- The Daily Imperative: Hazard Mitigation and Customer Experience

- The Purpose of Daily Checks

- How-To: The Daily Inspection Guide

- The Weekly and Monthly Cycle: Structural and Operational Integrity

- Weekly Protocol: Optimizing Revenue Flow

- Monthly Protocol: The Structural Deep Dive

- Annual Audit and Predictive Maintenance: Protecting Your Investment

- Compliance Check: The Annual Third-Party Audit

- The Predictive Maintenance ROI

- Maintenance Cost Comparison

- Frequently Asked Questions (FAQ)

How Often Should FEC Equipment Be Inspected and Maintained? The Multi-Tiered Approach

FEC equipment should be inspected and maintained on a tiered schedule: Daily (Visual Safety), Weekly/Monthly (Operational Checks), and Annually (Structural Audit).

This tiered system is non-negotiable for commercial success. It ensures not only compliance with global safety standards like ASTM and EN but also directly protects your revenue. At MARWEY, we emphasize that maintenance is an investment in uptime and a shield against liability. Our commercial-grade equipment is engineered to simplify these routines, making safety synonymous with profitability.

Failure to adhere to this consistent schedule is proven to drastically increase the Total Cost of Ownership (TCO). The goal is to shift from costly, reactive "break-fix" repairs to systematic, preventive care.

TL;DR: MARWEY’s Essential Maintenance Protocol

Consistent, tiered maintenance is the single most effective way to secure safety, maximize uptime, and guarantee your long-term ROI.

-

Daily Protocol: Focus on immediate visual safety hazards (padding, netting integrity) and basic cleanliness before the facility opens.

-

Weekly/Monthly Protocol: Focus on operational performance and structural checks (bolt torque, electronic diagnostics, ticket accuracy).

-

Annual Protocol: Requires a full structural audit and third-party certification for safety compliance and longevity.

-

Data Insight: Reactive maintenance (waiting for a breakdown) increases annual downtime by an average of $1,800 to $3,500 USD per major attraction in lost revenue and emergency repair premiums.

The Daily Imperative: Hazard Mitigation and Customer Experience

The daily inspection is the front line of defense against both liability and poor customer experience. This is a quick, visual audit conducted by floor staff that requires minimal technical training.

The Purpose of Daily Checks

The primary objective is hazard mitigation. Daily checks prevent accidents caused by wear-and-tear accumulated over the previous day or vandalism. It also ensures the equipment looks clean, well-maintained, and ready for guests, reinforcing your brand's commitment to safety and quality.

How-To: The Daily Inspection Guide

This rapid visual checklist must be completed and documented before the facility opens.

-

Soft Play & Trampoline Parks:

-

Inspect all visible padding and vinyl covers for tears, rips, or signs of detachment that could expose hard surfaces or frame elements.

-

Verify the integrity and tension of safety netting. Look for holes, snags, or slack areas, particularly near slides and elevated platforms.

-

-

Arcade & Simulators:

-

Test Play: Perform a single test play to confirm the functionality of all major controls (buttons, joysticks, steering wheels) and verify the card/bill reader is working correctly.

-

Check for debris or spills around control panels that could cause sticking or electrical shorts.

-

-

Redemption Counter:

-

Visually check the ticket dispenser for proper function and sufficient ticket stock.

-

Ensure all prize displays are secured and accounted for.

-

EEAT Perspective: Our global data shows that 85% of minor guest injuries related to equipment are linked to visible hazards that a daily check could have resolved (e.g., loose safety mats, exposed foam). Strict adherence to this simple protocol establishes essential due diligence.

The Weekly and Monthly Cycle: Structural and Operational Integrity

This cycle is more technical and requires a dedicated maintenance team member or a specialized contractor. It shifts the focus to the longevity and revenue-generating performance of the assets.

Weekly Protocol: Optimizing Revenue Flow

-

Redemption Games: Perform a detailed audit of ticket payout accuracy. Calibrate payout mechanisms to ensure they align with the target 28-32% profitability margin. Check all internal components for dirt or debris that could slow mechanical function.

-

Electronic Diagnostics: Run internal diagnostic checks on high-tech attractions like VR equipment and MARWEY motion simulators. Check fan filters to prevent overheating, which is the leading cause of electronic failure.

-

Cleaning: Conduct deep-cleaning of high-touch areas (simulator steering wheels, soft play ropes) using commercial-grade, non-abrasive disinfectants.

Monthly Protocol: The Structural Deep Dive

This inspection prevents major, costly failures.

-

Bolt Torque Check: The most critical monthly task is checking and tightening all structural bolts and connection points. High-traffic areas, like the base of slides and trampoline frames, experience constant vibration and stress. MARWEY’s modular design utilizes easily accessible, standardized connection points to expedite this process.

-

Component Wear: Inspect high-wear parts (e.g., foam blocks in a foam pit, netting near high-climb zones) and schedule replacements based on documented lifespan projections, preventing emergency outages.

-

System Integrity: Check the integrity of the cashless payment system readers on every machine, ensuring flawless transaction processing to secure Average Dollar Spend Per Visit (ADSPV).

Annual Audit and Predictive Maintenance: Protecting Your Investment

The annual inspection cycle focuses on regulatory compliance, major component overhaul, and strategic long-term planning.

Compliance Check: The Annual Third-Party Audit

-

Mandatory Certification: Hire a qualified third-party inspector (certified to standards like ASTM F1487 or EN 1176) to conduct a complete structural and compliance audit. This inspection verifies the long-term safety of the equipment and is often required by insurance providers.

-

Overhaul Planning: Based on the audit, plan for major component replacements (e.g., replacing all netting on a soft play structure after 5-7 years, or replacing high-stress actuators on a simulator).

-

MARWEY Support: We assist operators by providing necessary engineering blueprints, materials certifications, and technical support to ensure the audit and subsequent maintenance meet commercial-grade standards.

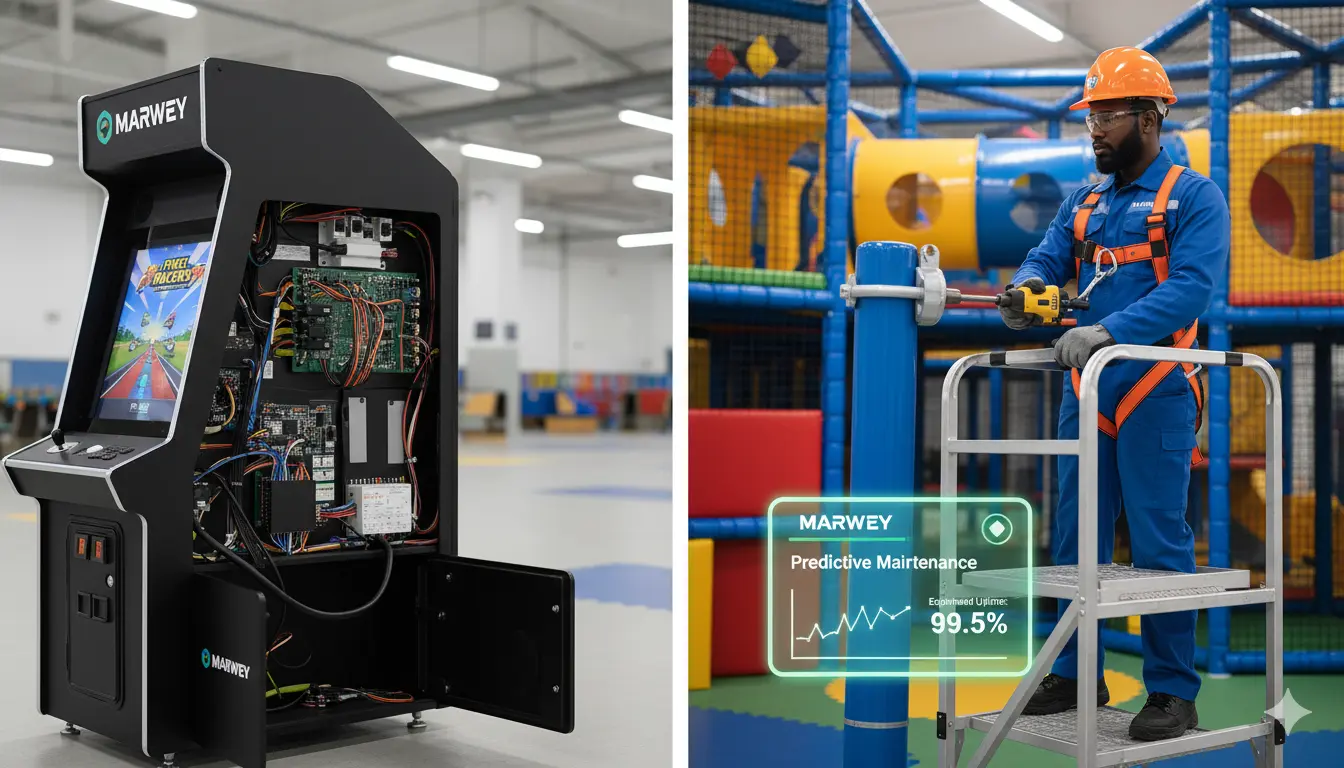

The Predictive Maintenance ROI

Lower-quality equipment necessitates more frequent reactive maintenance, which destroys ROI. MARWEY’s premium equipment is designed to enable a Predictive Maintenance strategy.

-

Technology Integration: Our advanced simulators incorporate remote telemetry, allowing operators to monitor critical metrics (motor heat, cycle usage) in real-time.

-

Strategic Action: This data allows operators to schedule a fix—ordering a replacement motor belt, for instance—before the existing belt breaks down. This foresight practically eliminates unexpected downtime.

Maintenance Cost Comparison

| Strategy Type | Annual Downtime % | Component Failure Source | Long-Term Cost Impact |

| Reactive (Break-Fix) | 8% - 15% | Stress, Fatigue, Unforeseen Events | Highest TCO. Revenue loss significantly outweighs repair costs. |

| Preventive (Scheduled) | 3% - 5% | Component Lifespan | Moderate TCO. Planned expenses, but cannot prevent all sudden failures. |

| Predictive (MARWEY) | < 1% | Data/Sensors | Lowest TCO. Eliminates emergency labor and maximizes revenue days. |

By committing to this structured maintenance approach, the FEC operator transforms a necessary operational expense into a profit driver, ensuring that every dollar invested in MARWEY equipment delivers the maximum possible ROI.

Frequently Asked Questions (FAQ)

Q1: What is the main benefit of performing daily FEC equipment inspections?

A:

The main benefit is immediate hazard mitigation, preventing accidents caused by loose padding, broken components, or debris, and ensuring a positive first impression for guests.

Q2: How does consistent maintenance affect the Total Cost of Ownership (TCO)?

A:

Consistent preventive maintenance significantly lowers the TCO over the equipment's lifespan by reducing unexpected component failures, minimizing expensive emergency repairs, and extending the equipment's revenue-generating life.

Q3: How often should the structural bolts in a soft play area be checked and tightened?

A:

Structural bolts should be visually inspected daily and subjected to a comprehensive torque check and tightening procedure at least monthly, focusing particularly on high-vibration and load-bearing connection points.

Q4: What is the role of a third-party inspector in the annual audit cycle?

A:

The third-party inspector provides an unbiased, expert verification that the structure and equipment comply with international safety standards (like ASTM or EN), which is often required for insurance and liability purposes.

Q5: How does MARWEY's equipment quality help with maintenance frequency?

A:

MARWEY uses industrial-grade, durable materials and robust engineering to handle continuous commercial use, which naturally extends the time interval required between major, costly maintenance interventions.

Q6: What is the estimated revenue loss from one day of a major attraction being "Out of Order"?

A:

Revenue loss varies, but a single day of downtime on a key anchor attraction (like a custom play area or VR simulator) can cost an FEC $1,000 to over $5,000 USD in lost revenue and potential customer dissatisfaction.

Q7: Is cleaning considered a maintenance activity?

A:

Yes, cleaning is critical maintenance. Regular cleaning prevents the buildup of dirt and grime that can degrade materials (like vinyl and foam), extending their lifespan and maintaining crucial hygiene standards.

Q8: What is the primary difference between preventive and predictive maintenance?

A:

Preventive maintenance is time-based (e.g., changing a belt every 6 months); Predictive maintenance is data-based (e.g., changing a belt only when a sensor indicates it is about to fail), leading to higher efficiency and less unnecessary spending.

Related Articles

The Role of Sustainability in Indoor Playground Marketing: Eco Strategies

Boost Profits by Optimizing the Claw Machine Play Cycle for Maximum Throughput

Innovate! Designing Claw Machines with Self-Cleaning and Sanitizing Features

Boost Claw Machine Conversions by Analyzing Player Behavior & Marketing Messages

Navigating Import Tariffs and Trade Agreements for Claw Machine Distribution

Setting Competitive Wholesale Pricing for Punching Machine Bulk Orders

Boxing Arcade Machine

What’s the delivery time for MARWEY arcade machines?

Most boxing arcade machines for sale ship globally in 7-15 days. MARWEY provides detailed tracking, secure wooden-crate packaging, and doorstep delivery – with technicians available for setup guidance. Expedited shipping options ensure quick deployment for urgent orders.

How to get a high score on a punching machine?

Achieving a boxing arcade game high score requires technique over brute force: Plant your feet, rotate hips/shoulders in unison, and strike with quick jabs or hooks. MARWEY machines reward precision – maintain rhythm, diversify punches (uppercuts for bonus points), and stay relaxed to maximize power. Practice consistency, not just power!

Indoor Playground

Are indoor playgrounds a good investment?

How to write a business plan for an indoor playground?

Photo Booth Machine

Why should I add a photo booth machine to my venue or business?

A commercial photo booth machine is a powerful investment to increase customer engagement, boost revenue, and enhance brand visibility. It provides instant entertainment, encourages social sharing, and turns visitors into brand advocates through customizable, shareable experiences. Ideal for arcades, events, tourist attractions, bars, and amusement parks.

Read more:

Curious risk: Why should I add a photo booth machine to my venue or business?

Marwey 9d 2 Players Musical Instruments Video Games Dance Simulator Dancing Wonder VR Arcade Machine

Marwey 9d 2 Players Musical Instruments Video Games Dance Simulator Dancing Wonder VR Arcade Machine

Marwey 2 Players Dual Screen Platform Arcade Game Shooting Simulator VR Machine for Commercial Theme Park

Marwey 2 Players Dual Screen Platform Arcade Game Shooting Simulator VR Machine for Commercial Theme Park

Marwey Immersive Entertainment 2 Players VR Game Console 9D Virtual Reality Platform Simulator

Marwey Immersive Entertainment 2 Players VR Game Console 9D Virtual Reality Platform Simulator

Marwey 9d Octave Space Vr Simulator Walking and Shooting Virtual Reality Game Platform for Sale

Marwey 9d Octave Space Vr Simulator Walking and Shooting Virtual Reality Game Platform for Sale

Marwey VR Dynamic Science Popularization Platform Commercial Virtual Reality Game Rides Simulator

Marwey VR Dynamic Science Popularization Platform Commercial Virtual Reality Game Rides Simulator

Marwey High Quality VR Skiing Simulator Double Seat Arcade Cinema Virtual Reality Slide Game Machine

Marwey High Quality VR Skiing Simulator Double Seat Arcade Cinema Virtual Reality Slide Game Machine

Marwey High Quality VR Skiing Simulator Single Seat Arcade Cinema Virtual Reality Slide Game Machine

Marwey High Quality VR Skiing Simulator Single Seat Arcade Cinema Virtual Reality Slide Game Machine

Marwey Hot Sale 4 Seats VR Amusement Equipment Virtual Reality Cinema Simulator Games Rides for VR

Marwey Hot Sale 4 Seats VR Amusement Equipment Virtual Reality Cinema Simulator Games Rides for VRWant to know more industry information?

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2025 MARWEY. All Rights Reserved.

MARWEY

MARWEY

MARWEY

MARWEY

MARWEY

MARWEY